Maintaining industrial fluids clean at all times can have a tremendous impact on your operations and performance. It´s the difference between unscheduled downtime, emergency repairs, and meeting production goals without major problems. (Download Service Profile)

Ensure Sustained Performance

We Are The Right Fit

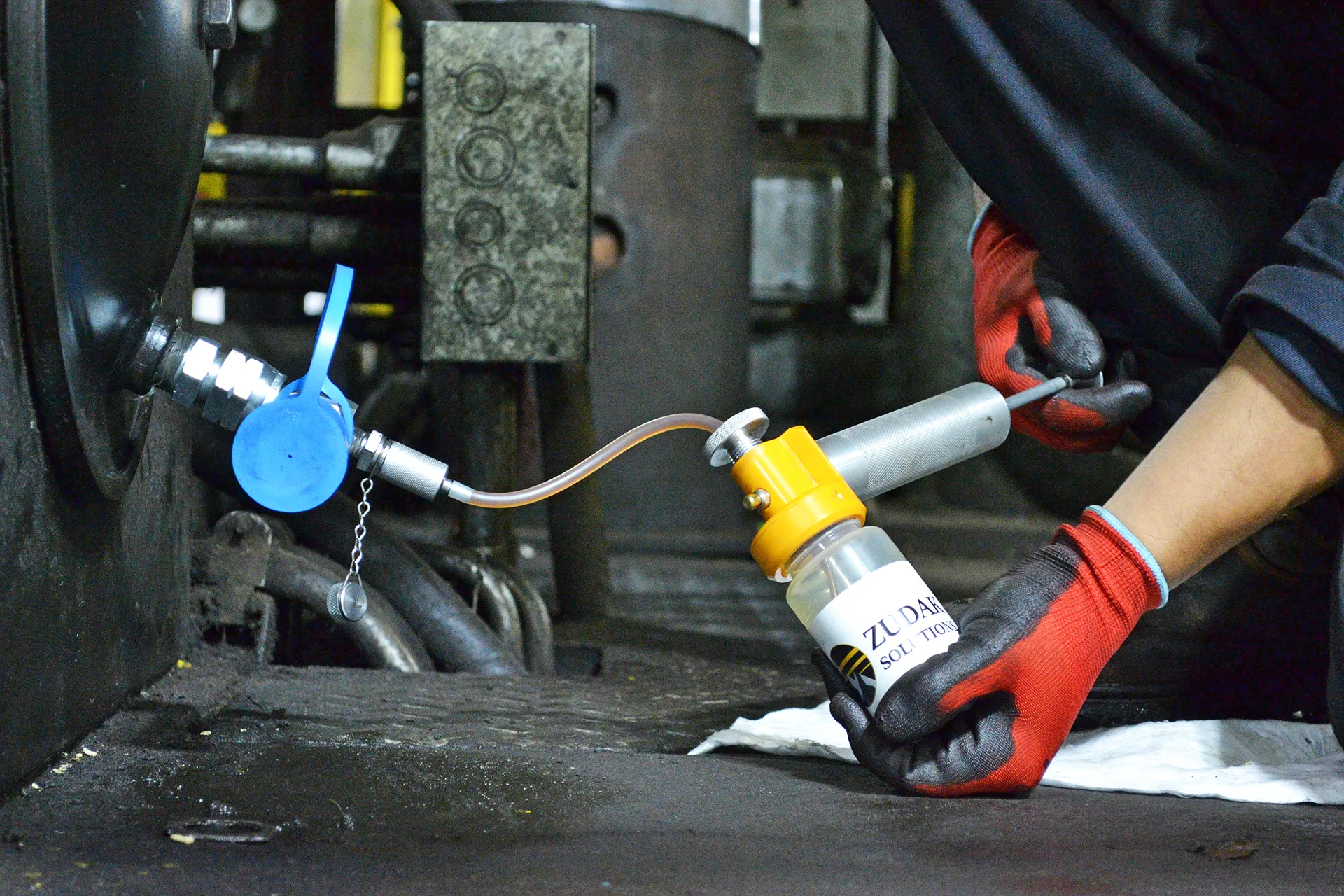

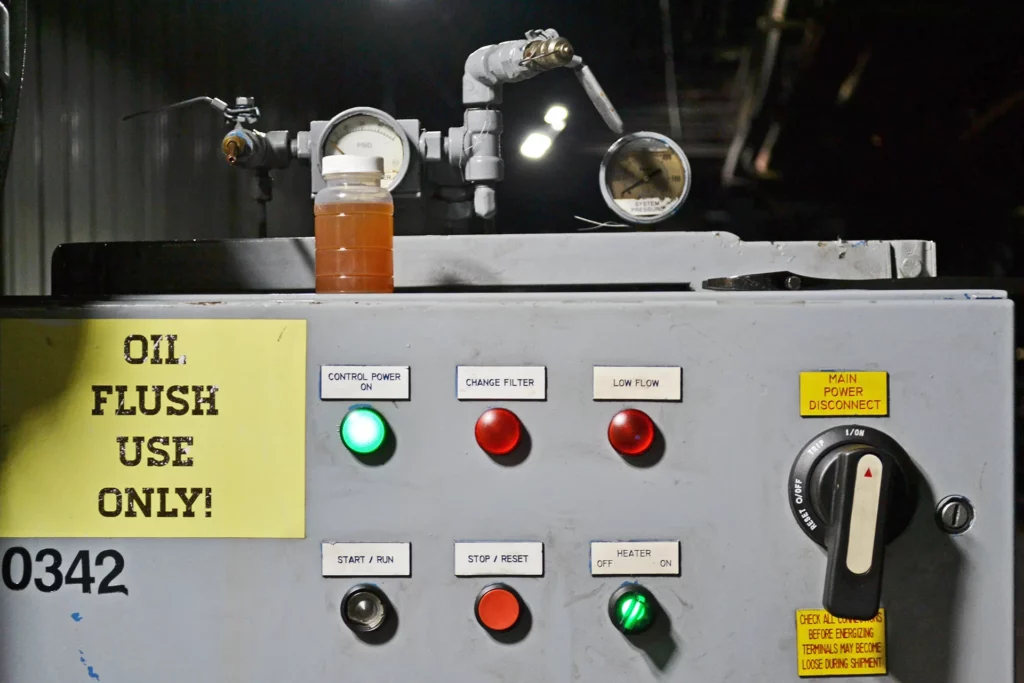

Our engineers are specifically trained to render the service for almost any kind of machine or facility. We use powerful external pumps with a special filtration system that will filter through many scheduled runs all the unwanted material that should not be in your fluids

Some systems can have their fluids contaminated via reverse osmosis, that’s why Zudak’s engineers will assess every particular situation and put in place the necessary approach to ensure success.

Frequently conducting this process will prevent your fluids from containing:

– Particulates

– Dirt & Debris

– Water

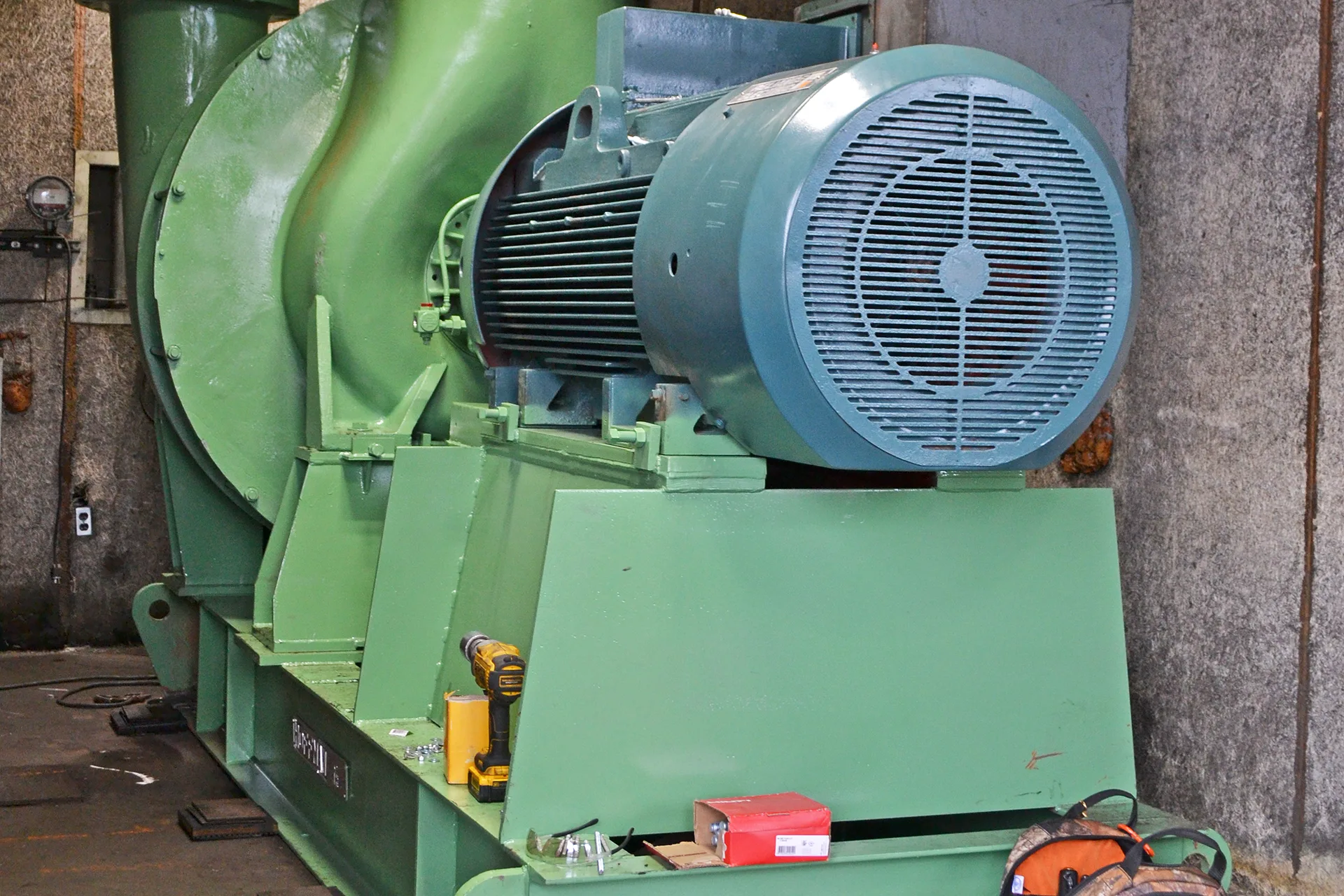

Some of the most demanded applications for this service are:

– Pre-operational filtration flushing

– Onstream full flow filtration

– Sidestream (kidney loop) industrial filtration system

– Waste stream flushing before disposal

– Cooling medium filtration

How It Works

Once we start working with you, we’ll execute our proven process to streamline the solution without wasting any time.

Each service selected for execution will be reviewed with your site team to ensure it encumbers all pertinent stakeholders, deliverables, and timelines. Our approach to any project includes the following 3 basic steps:

Planning and Pre-engineering Phase

In this stage, we’ll define together the scope of work, technical constraints, and required timeline. We will render a project proposal for your review and approval.

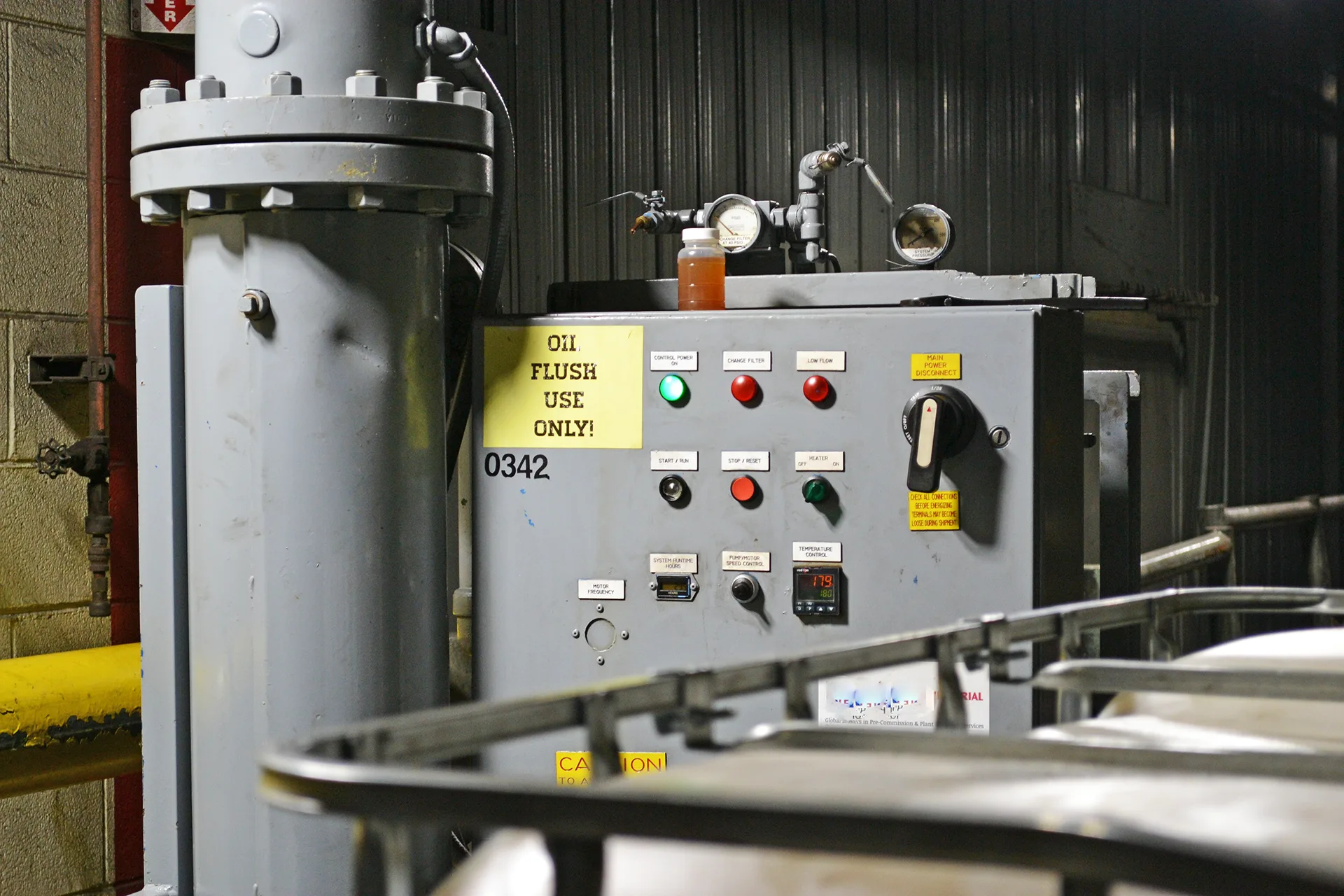

Execution Phase

After your approval, our team of technicians and field engineers will execute the established plan of action, and complete your system´s filtration. And ultimately achieving the cleanliness goals.

Review Phase

Upon completion, we’ll provide a Completion Report highlighting and explaining the results achieved.